Comprehensive Packaging Machine Repair Service for Quick and Effective Fixes

Comprehensive Packaging Machine Repair Service for Quick and Effective Fixes

Blog Article

Comprehending the Secret Components and Repair Strategies for Product Packaging Device Upkeep

Efficient maintenance of product packaging devices pivots on a complete understanding of their key parts, consisting of the frame, drive system, and securing systems. Acknowledging common upkeep problems, coupled with the execution of preventative methods and troubleshooting strategies, can dramatically boost device reliability. Furthermore, the selection of repair work practices, including making use of OEM components and the significance of certified technicians, plays a crucial duty in decreasing downtime. To absolutely understand the intricacies of these systems and their upkeep, one need to think about the more comprehensive implications of disregarding these crucial methods.

Key Components of Packaging Devices

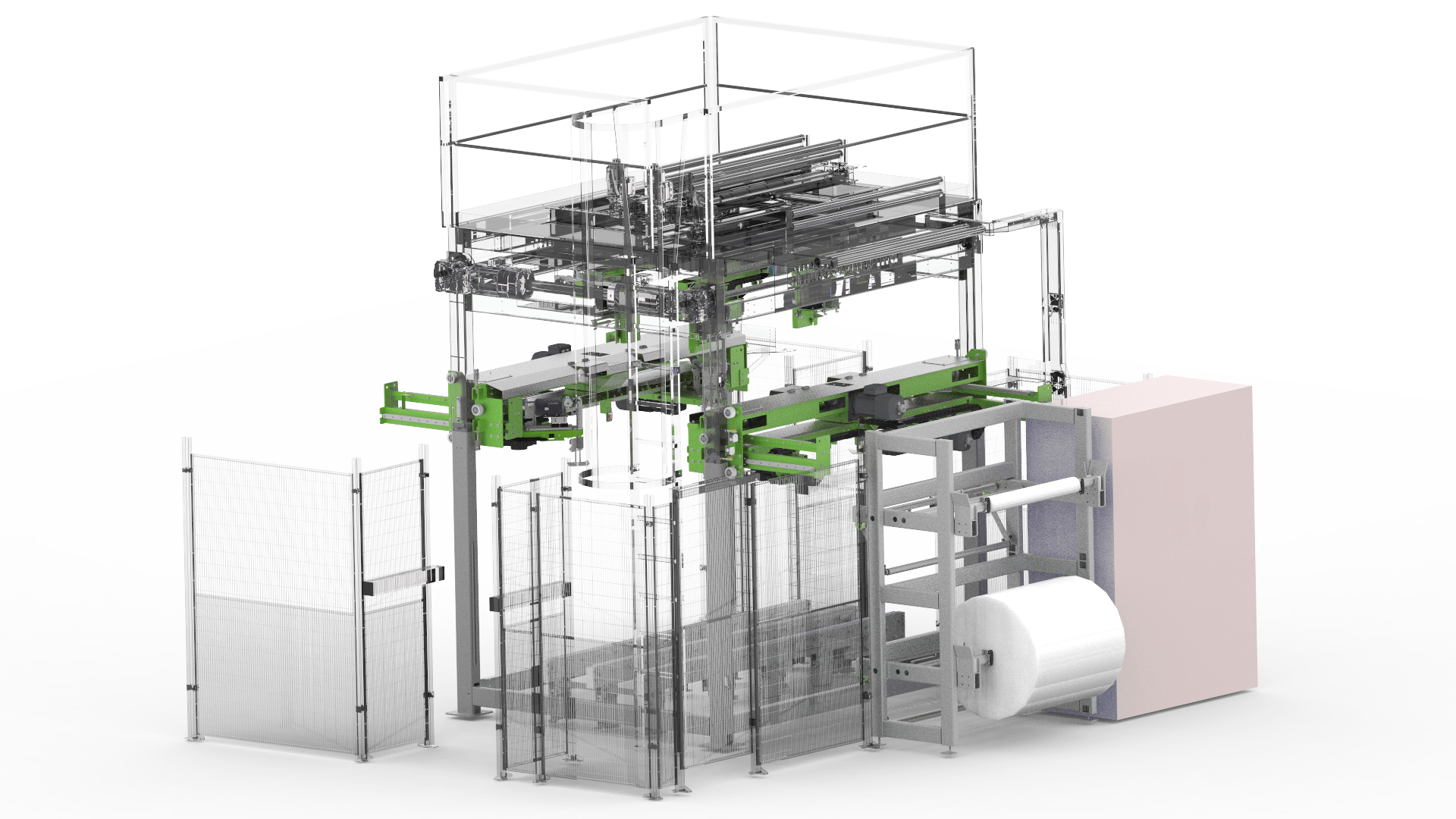

Packaging devices include numerous vital components that interact to guarantee efficient and effective product packaging procedures. At the core of these equipments is the structure, which provides architectural honesty and houses the various operating components. The drive system, typically a mix of electric motors and equipments, helps with the motion of parts, making it possible for specific procedure throughout the product packaging cycle.

Another vital element is the conveyor system, which moves products through different phases of the product packaging procedure. This is commonly enhanced by sensing units and controls that monitor the position and speed of things, ensuring synchronization and minimizing errors. The filling system is critical for accurately giving the appropriate amount of product into packages, whether in fluid, powder, or strong form.

Sealing devices, consisting of warm sealers or glue applicators, play an essential function in securing plans, stopping contamination and prolonging service life. In addition, identifying systems are essential for providing necessary item info, guaranteeing conformity with guidelines. The control panel, equipped with straightforward interfaces, enables drivers to handle equipment functions, screen efficiency, and make modifications as required, making certain optimal efficiency and efficiency in packaging procedures.

Common Maintenance Concerns

Effective operation of product packaging machines depends greatly on normal maintenance to stop usual issues that can interfere with manufacturing. Among these problems, mechanical damage is prevalent, especially in parts like motors, seals, and conveyors, which can bring about unexpected downtimes. Furthermore, imbalance of components can cause ineffective procedure, causing products to be improperly packaged or damaged during the procedure.

One more usual upkeep concern entails the buildup of dirt and debris, which can interfere with the device's sensors and moving parts. packaging machine repair service. This not only impacts performance however can likewise present safety and security threats. Furthermore, lubrication failures can lead to enhanced friction, leading to overheating and eventual component failure.

Electrical problems, typically coming from loose connections or worn-out circuitry, can interrupt equipment features, causing considerable production delays. Last but not least, software program glitches due to inappropriate arrangements or out-of-date programs can impede the machine's procedure, necessitating prompt treatment. Addressing these usual maintenance concerns proactively is essential for making certain ideal performance and long life of packaging equipment.

Preventative Maintenance Strategies

Carrying out preventative maintenance approaches is vital for sustaining the performance and dependability of product packaging devices. These strategies include a systematic technique to maintenance, concentrating on the normal assessment and servicing of devices to preempt possible failures. By sticking to a set up maintenance program, drivers can identify deterioration on parts before they cause significant malfunctions.

Crucial element of a preventative upkeep approach include routine assessments, lubrication, cleaning, and component replacements based upon manufacturer suggestions. Making use of checklists can improve this procedure, guaranteeing that no essential tasks are forgotten. Additionally, maintaining precise records of upkeep tasks aids in tracking the maker's efficiency with time, promoting notified decision-making regarding like it future maintenance needs.

Training personnel on the value of preventative upkeep improves compliance and promotes a culture of proactive care. Executing a predictive maintenance component, utilizing data analytics and sensing unit modern technology, can better maximize equipment efficiency by forecasting failings before they happen.

Repairing Strategies

When encountered with malfunctions or inefficiencies in product packaging equipments, utilizing methodical troubleshooting techniques is essential for recognizing and settling problems swiftly. The initial step in reliable troubleshooting is to develop a clear understanding of the equipment's functional parameters and performance metrics. This entails assessing the maker's specs, in addition to any type of error codes or notifies presented.

Following, operators ought to conduct an aesthetic examination, looking for apparent indications of wear, imbalance, or damage. This frequently consists of taking a look at belts, sensing units, and gears to identify possible sources of malfunction. Collecting operational data, such as production rates and downtime logs, can also give insights into recurring problems.

As soon as prospective problems are recognized, utilizing a sensible approach to isolate the origin reason is important. This might require screening individual elements or systems in a regulated fashion. Engaging in discussions with operators that connect with the equipment on a regular basis can generate valuable feedback regarding Visit Website unusual habits or patterns.

Fixing and Substitute Best Practices

An extensive understanding of repair and substitute finest methods is vital for keeping the durability and effectiveness of packaging equipments. On a regular basis evaluating the condition of equipment elements enables prompt intervention, protecting against even more significant concerns that can cause costly downtimes.

When fixings are required, it is important to make use of OEM (Original Devices Manufacturer) components to ensure compatibility and efficiency. This not only maintains the integrity of the equipment but additionally supports warranty contracts. Additionally, it is a good idea to maintain a stock of crucial extra parts to assist in quick replacements and minimize functional disturbances.

For complicated fixings, engaging qualified specialists with specialized training in product packaging machinery is suggested. They have the know-how to diagnose issues properly and execute repair services successfully. Additionally, recording all repair activities and components replacements is vital for maintaining a comprehensive upkeep background, which can help in future troubleshooting.

Last but not least, implementing a proactive method, including routine assessments and anticipating upkeep strategies, boosts the dependability of packaging devices. By adhering to these best methods, services can make sure ideal maker efficiency, minimize operational dangers, he has a good point and extend equipment lifespan.

Conclusion

In conclusion, a detailed understanding of packaging maker parts and effective maintenance methods is essential for ideal efficiency. By applying these practices, organizations can guarantee the long life and performance of product packaging machines, eventually contributing to enhanced functional performance and lowered costs (packaging machine repair service).

Effective maintenance of packaging devices hinges on a complete understanding of their key components, including the frame, drive system, and sealing systems.Efficient operation of packaging makers depends greatly on routine upkeep to stop usual concerns that can disrupt manufacturing.Implementing preventative maintenance strategies is essential for maintaining the effectiveness and reliability of product packaging makers. In addition, maintaining accurate records of maintenance tasks help in tracking the maker's efficiency over time, assisting in notified decision-making concerning future maintenance needs.

Report this page